Rapid milk powder production line! Launching in two weeks, producing 10 cans in one minute,ensuring the safety and controllability of the entire industry chain.

A super efficient milk powder production line has been newly launched in the dry two river basins of the Middle East! It can produce 10 cans of formula milk per minute while also meeting GMP level safety standards, allowing the desert to produce fresh and safe formula milk.

This production line is completely different from traditional production lines. It does not require manual intervention throughout the entire process, from empty cans to finished milk power, in one go. Every step has clever technological ideas, which are both fast and safe. How is it specifically operated? Now follow in my footsteps in my footsteps and take a look.

Empty cans quickly "line up"

The 800 bottle sorting machine is the "vanguard" of the production line, which can quickly sort out scattered empty cans of 400g and 900g scattered neatly, preparing adequately for subsequent processes.

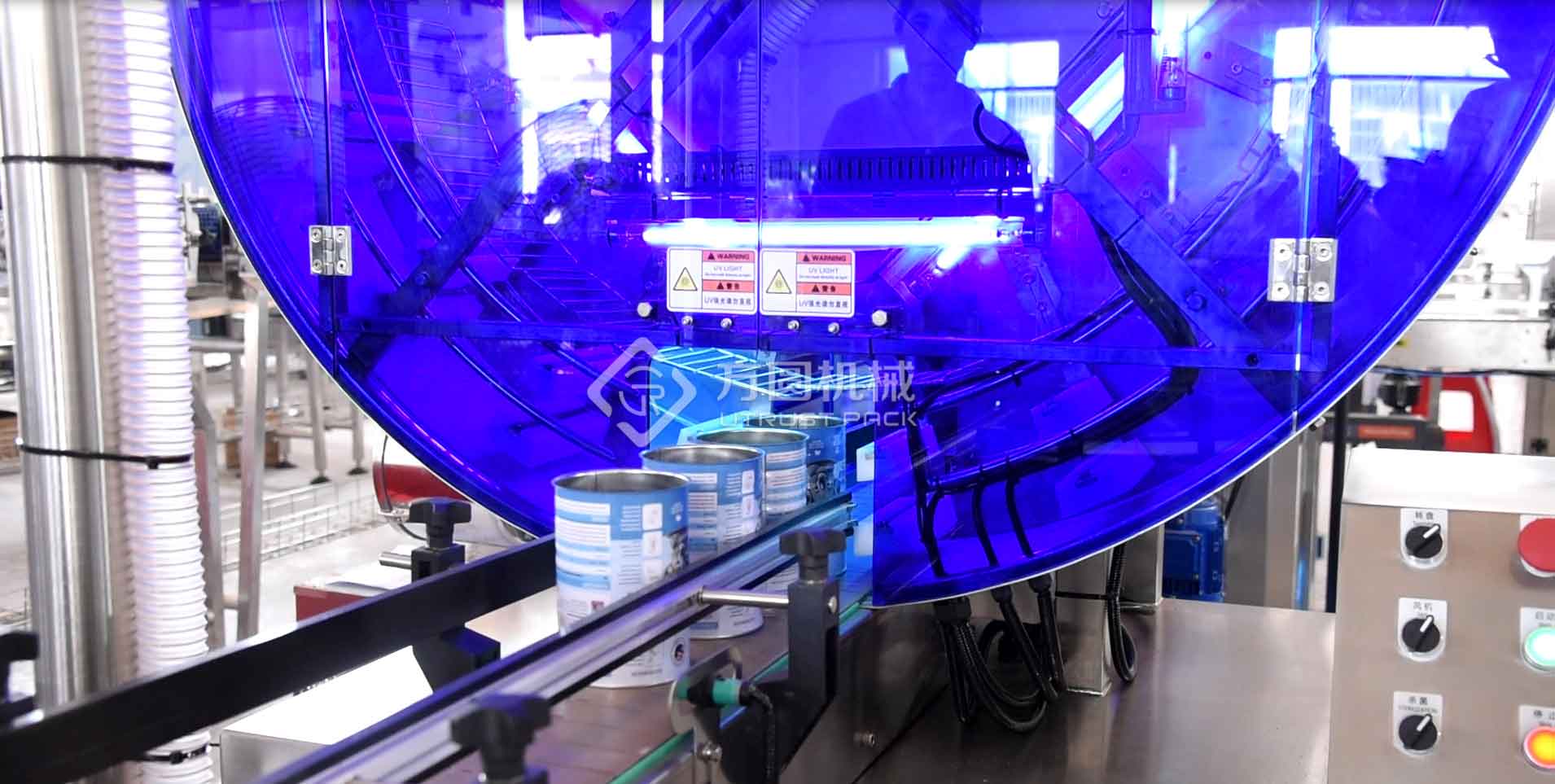

360° no dead angle sterilization

Empty cans must undergo sterilization treatment before being filled with milk powder. Our UV rotary sterilization equipment will perform a comprehensive "photon SPA" on each empty can, will 306° no dead angle irradiation, thoroughly killing bacteria inside the can and eliminating pollution from the source.

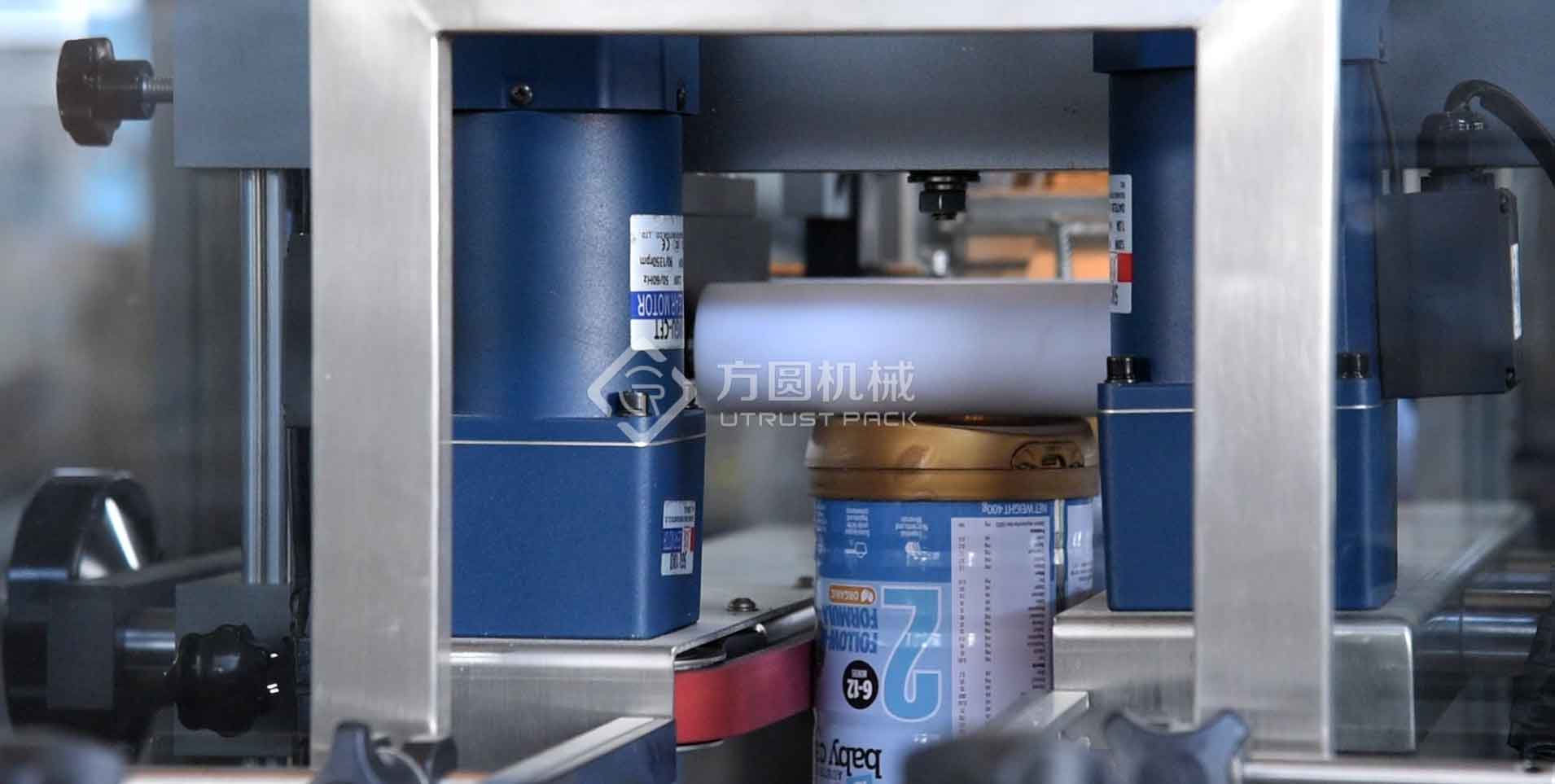

5-minute quick specification change filling

The filling process is the "core brain" of the entire production line. The single head servo filling equipment can accurately control the weight of each can of milk powder, without overfilling or underfilling. In addition, switching between 400g and 900g specifications only takes 5 minutes, eliminating the need for long downtime for debugging, which greatly improves production efficiency.

Filling nitrogen to lock in freshness, like wearing a "preservation armor"

First, clean the air in the jar, then inject high-purity nitrogen gas, and seal the jar. In this way, the milk powder is like wearing a layer of "preservation armor", which is not easy to oxidize or clump, and can maintain its delicate and appearance when it is first produced.

Flip the can, cover it, and press it tightly in one step.

The final step is also fully automatic operation, which involves flipping the can, capping, and pressing the lid in one go. The action is fast and accurate, leaving no scratches on the can body loosening of the lid, perfectly ensuring that each of milk powder is intact and undamaged.

The whole process is in compliance with the GMP standards for powdered infant formula food, and the process conforms to the national mandatory safety standards. The positive pressure cleaning area isolates pathogenic bacteria and cross contamination from the source, ensuring the comprehensive safety of babies'diet. The efficient and reassuring intelligent production process allows babies in the Middle East to also enjoy fresh and high-quality local milk powder.