¡Ver es más tranquilizador!

Tres ardillas:El viaje del relleno de almendras

Cuando piensas en frutos secos, ¿qué te viene primero a la mente? ¿Los fragantes y crujientes ingredientes de tu cereal de desayuno o esos irresistibles snacks que saboreas mientras te das un atracón de zapatos? Estos pequeños superalimentos se han convertido poco a poco en nuestros acompañantes saludables favoritos. Las almendras aportan proteínas de alta calidad para un rápido impulso de energía, mientras que los ácidos grasos insaturados de los anacardos nutren tanto el cuerpo como la mente; cada fruto seco es un regalo de la naturaleza. Pero quizás te preguntes: ¿Qué camino recorren estos frutos secos desde el huerto hasta el frasco, conservando sus nutrientes y garantizando una entrega segura a nuestras mesas? Hoy, sigamos la perspectiva de una almendra en el taller de relleno transparente de Three Squirrels y descubramos los secretos de esta delicia.

Progreso del viaje: 60%......

Progreso del viaje: 60%......

El primer rayo de sol de la mañana trepaba suavemente por la cortina de cristal del taller, con un suave "ding". Parecía el preludio de la inauguración de una nueva línea de producción. Y yo, una almendra recién despertada del almacén de materias primas, observaba con curiosidad este lugar fresco: el taller de llenado transparente que acaba de terminar Tres Ardillas.

La noche anterior, el sistema inteligente ya había calculado la producción del día según el pedido, siguiendo el principio de "producir solo lo necesario hoy, nunca de la noche a la mañana". Los anacardos y cacahuetes que estaban a mi lado se enviaron primero a la caja de preprocesamiento "Little Sun", para preparar la cantidad necesaria para el siguiente llenado.

¿Crees que es tan fácil seguirme al interior del taller? ¡Claro que es imposible! Debes ponerte un traje blanco antipolvo, lavarte bien las manos y desinfectarlas, y luego pasar por una ducha de aire de 20 segundos para eliminar el polvo, para obtener la entrada al área limpia de nivel 300.000. En cuanto entré al taller, una nueva línea de llenado lineal me llamó la atención, y mi maravilloso viaje comenzó oficialmente.

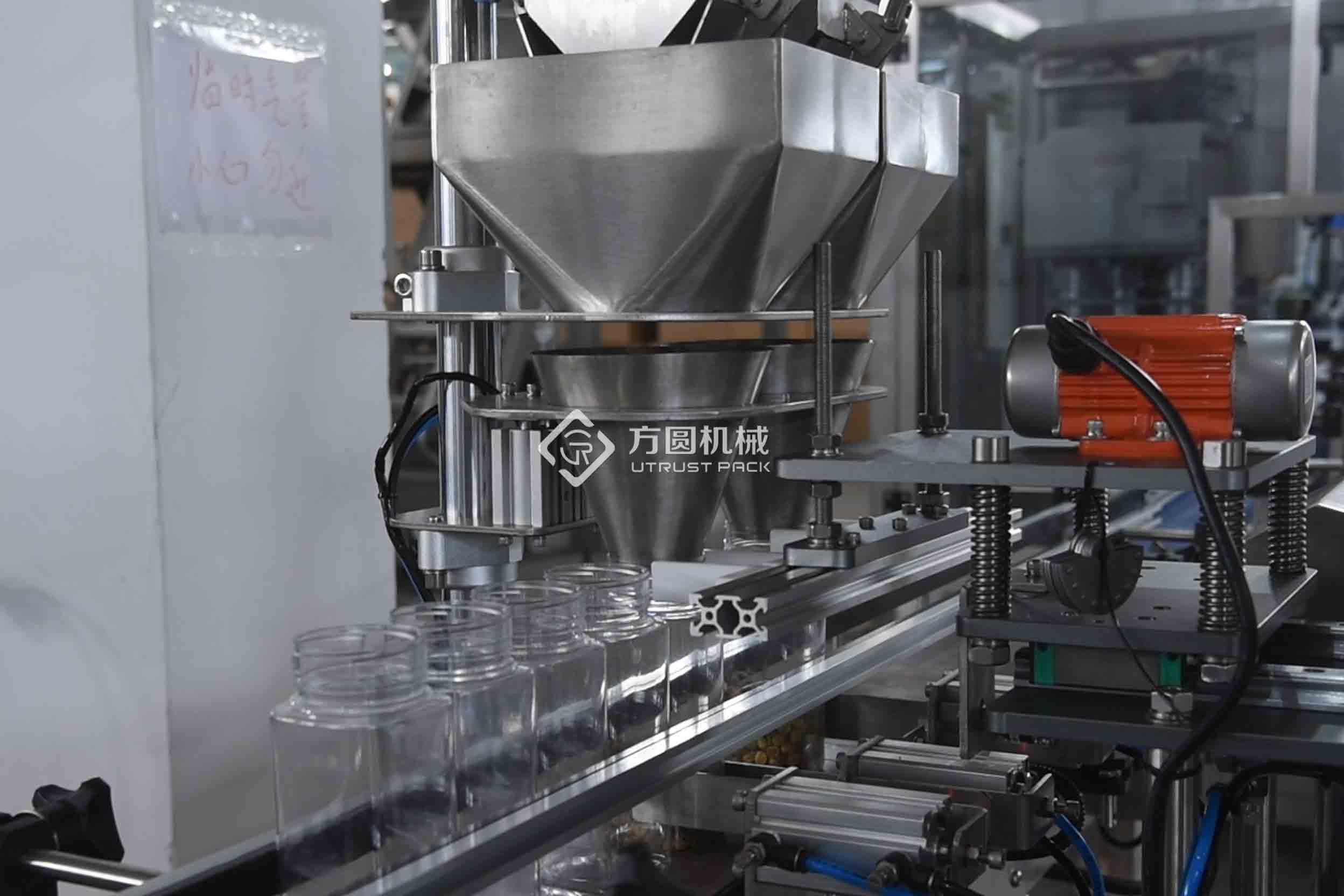

Primera parada:Máquina de alimentación lineal totalmente automática,

permitiendo que cada fruto seco comestible sea enlatado con precisión sin desperdicio

La primera parada fue la máquina de alimentación lineal totalmente automática, que contaba con dos estaciones duales flexibles, como las patas delanteras redondas de una ardilla, abriendo su arco a izquierda y derecha, y estaba muy ocupada. La báscula combinada proporcionada por el cliente nos vertió con precisión a mí y a mis amigos en una tolva desmontable de 55 mm, y entonces la plataforma vibratoria comenzó a funcionar con un "golpe". Con una ligera vibración, mis amigos y yo nos acostamos obedientemente en la lata, evitando los huecos que dejaba la lata al apilarla. Con un funcionamiento eficiente de 30 a 40 latas por minuto, cada lata se llena hasta el borde y no se desperdicia ni una sola nuez.

Segunda parada: Máquina tapadora de seguimiento: la maestra del sellado que es constante,

Preciso y rápido, garantizando que cada lata esté sellada de forma segura

Después de despedirme del alimentador, me senté en el frasco y llegué a nuestra segunda parada: la siguiente máquina tapadora. Como se puede ver desde el frente, la tapa cuadrada agarraba con cuidado la tapa y el personal la cerraba. En el siguiente segundo, el brazo robótico servo de 3 ejes actuó como una precisa "mano grande", agarrando firmemente la tapa y completando el cierre. Lo que es aún más impresionante es que... El brazo robótico también puede lograr retroalimentación de torque en tiempo real, asegurándose de que cada tapa de lata esté bien apretada, sin aflojarse ni perder aire, y sin que esté demasiado apretada para abrirla.Se consigue una velocidad de salida estable de 50 botellas por minuto, y no hay necesidad de entrar en pánico en caso de cambiar el tipo de lata. Con solo un clic, el dispositivo se puede ajustar para adaptarse a la "altura, altura, peso y delgadez" de diferentes latas. El cambio se puede completar rápidamente en 3 minutos., y la eficiencia se puede maximizar directamente.

Tercera estación: Sellado de papel aluminio + Codificación de trazabilidad

Mantiene la frescura de forma segura y cada lata puede rastrearse hasta su origen.

Tras enroscar suavemente la tapa, me deslicé con firmeza hacia el túnel de inducción electromagnética de la tercera estación. Con un suave chisporroteo, la película de aluminio se adhirió firmemente a la boca de la lata gracias a la inducción electromagnética. Esta operación logra un sellado sin fugas y es clave para conservar la frescura.

En cuanto terminé de sellar, volví a la impresora de inyección de tinta y vi un código de trazabilidad exclusivo en la parte superior de la lata. Este pequeño código es como mi "certificado de identidad". Los consumidores solo tienen que escanearlo para ver de qué huerto provengo, por qué línea de producción pasé y cuándo se completó el llenado. Toda la información se puede visualizar para todos.

Cuando mis compañeros y yo colocamos cuidadosamente el código de trazabilidad completo en el área de producto terminado, supe que este viaje de llenado transparente había llegado a un final exitoso.

Desde las ramas del huerto hasta el taller limpio y ordenado, desde las nueces esparcidas hasta la deliciosa comida perfectamente empaquetada, la Fábrica Transparente Tres Ardillas utiliza un proceso de producción totalmente visible para envasar constantemente frescura, seguridad y diversión en las latas. Y nuestra misión final es llegar a las manos de todos con este corazón y total sinceridad, entregando alimentos deliciosos y reconfortantes que pertenecen exclusivamente a la familia de las ardillas.