La máquina selladora de latas de nitrógeno al vacío semiautomática presenta un diseño avanzado, una estructura razonable y un funcionamiento fácil de usar, lo que la convierte en una solución de envasado esencial e ideal para las industrias alimentaria, farmacéutica, del té y química. Después del sellado, el contenido de oxígeno residual se reduce a menos del 3%, lo que prolonga efectivamente la vida útil del producto.

Artículo No :

UT130Región original :

Guangzhou ChinaTiempo de espera :

10 days after receiving depoistPuerto de embarque :

GuangzhouPago :

TTLa orden mínima :

1

Especificación

| Función | Llenado de nitrógeno al vacío, enlatado de latas, sellado de latas, sellado de latas |

| Rodillos de sellado | Rodillos 1 par (1er rollo de costura/2º rollo de costura) |

| Velocidad de sellado | 5-6 latas/min |

| Altura de sellado | 40-190 mm (ajustable) |

| Diámetro de sellado | 50-153 mm |

| Voltaje | 220V, 50/60Hz |

| Fuerza | 2kW |

| Peso | 200 kg |

| Dimensión | 750*1030*1700MM (largo*ancho*alto) |

| Fuente de aire | 0,6-0,8 MPa |

Características

* Diseño de última generación, el las latas no giran Durante el proceso de sellado, solo los rodillos de sellado giran para completar el sellado, confiable y seguro, especialmente adecuado para materiales frágiles y envases de líquidos.

* Los rodillos de sellado y el cabezal del portabrocas están hechos de acero inoxidable 440C, que es extremadamente duro y no es fácil de oxidar, con una vida útil de más de 6 millones de dosis o 5 años.

* En el caso de llenado de vacío y nitrógeno, el contenido de oxígeno residual puede alcanzar por debajo del 3%.

* Puede completar las funciones de aspiración, llenado de nitrógeno y sellado en la cámara de vacío de una sola vez.

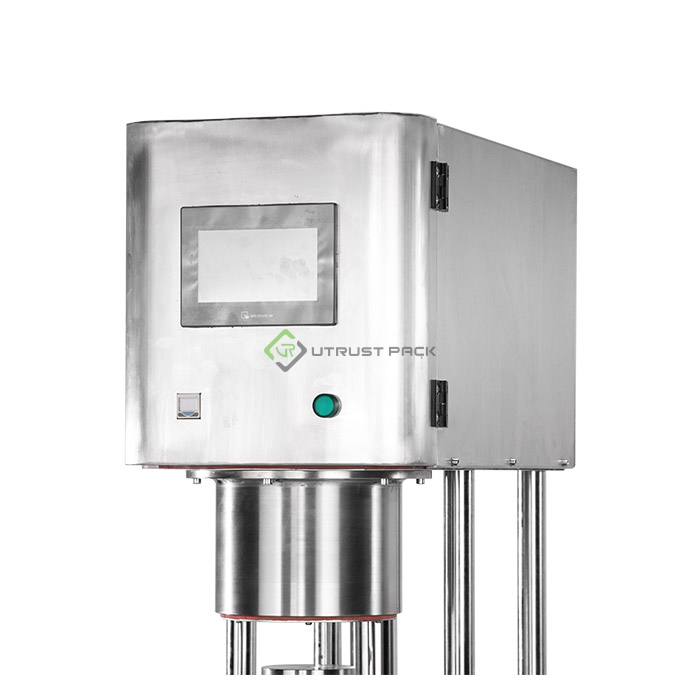

* Cuenta con un sistema de control PLC y una interfaz de pantalla táctil, lo que lo hace simple y fácil de operar.

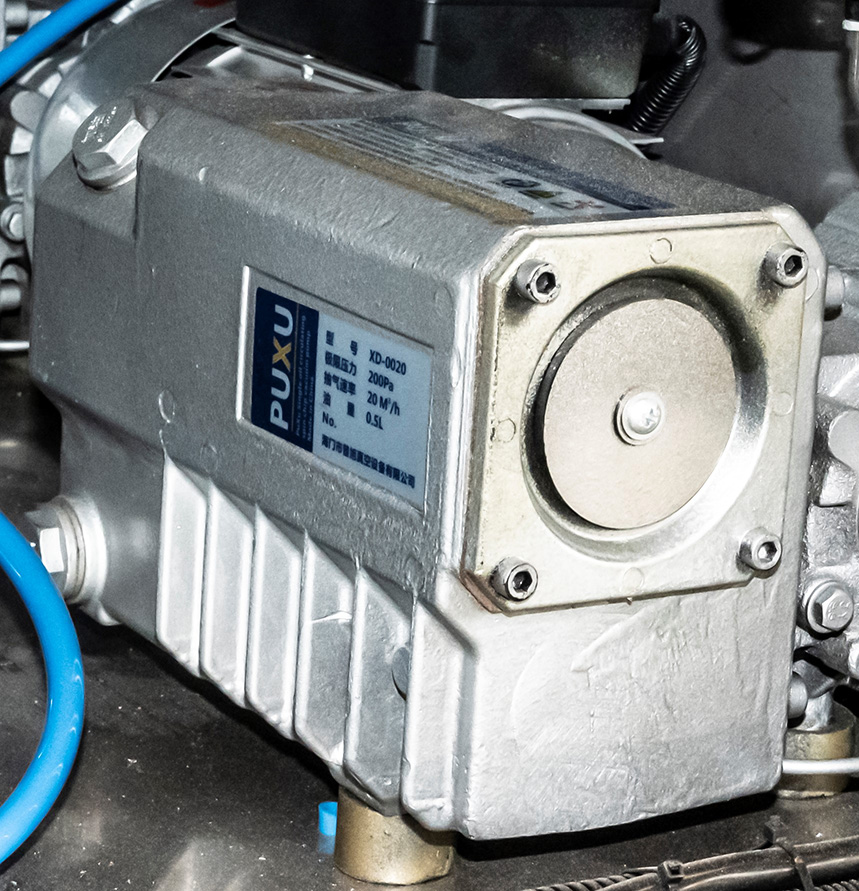

* Se puede lograr un grado de vacío extremadamente bajo con la bomba de vacío de alta presión dentro de la máquina.

* La máquina y las piezas principales están hechas de acero inoxidable 304 y cumplen con los estándares de la industria alimentaria, médica y sanitaria. Adecuado para Industria alimentaria, médica, química, etc.

* Todos los aparatos eléctricos y componentes neumáticos son fabricados por fabricantes reconocidos en el país y en el extranjero, de calidad confiable y estable.

Descripción del Producto

Máquina semiautomática de sellado de nitrógeno con lavado de tarros de chocolate para beber

Mostrar detalles

|  |  |

Rodillo de sellado de acero inoxidable 440C. 1.Extremadamente duro y no es fácil de oxidar 2.La vida útil es de más de 6 millones de latas o 5 años. | Control PLC y sistema de pantalla táctil. 1.Simple y fácil de usar 2. Varios idiomas | La bomba de vacío está oculta dentro de la máquina. 1.Bomba incorporada 2.Listo para el vacío |

|  |  |

Cámara de vacío 1.Aspirar, llenar con nitrógeno y sellar la cámara de una sola vez | Contenido de oxígeno residual inferior al 3% 1.Mantener la frescura del producto 2.Extender la vida útil de los alimentos de los alimentos. | Botón de operación 1. Simplemente presione los dos botones verdes al mismo tiempo para sellar la lata. |

Aplicaciones

Servicio Preventa

* Soporte de consultas y consultoría.

* Ver nuestra fábrica

* Soporte de pruebas de muestra.

Servicio postventa

* Capacitación sobre cómo instalar la máquina, capacitación sobre cómo utilizar la máquina.

* Ingenieros disponibles para dar servicio a maquinaria en el extranjero.

* 1 año de garantía, brinde comentarios dentro de 2 horas y brinde mantenimiento dentro de 48 horas.

Preguntas frecuentes

1. ¿Cuáles son sus servicios de instalación? | 2. ¿Qué pasa con su garantía de calidad? |

| Manual de usuario y vídeos de soporte para instalación, depuración, funcionamiento de la máquina. Te indicará cómo Usa bien esta máquina. | La máquina taponadora de botellas manual Ropp Cap para refrescos Drink Bottles tiene 1 año de garantía, todas las piezas de la máquina pueden ser reLugares dentro de 1 año si se rompe (sin incluir los hechos por el hombre). |

| 3. Si tenemos un pedido muy especial para la línea de producción, ¿podrían ayudarme a hacer el diseño? | 4. ¿Puedo visitar su fábrica? |

| Diseñador mecánico experimentado, diseño personalizado. proporcionó. | Sí, bienvenido por favor. |

| 5. Si tenemos muestraarchivos de nuevos productos, ¿Puedes ayudar a analizar y diseñar la máquina? | 6. ¿Tiene certificado? |

| Sí. Nuestro departamento técnico puede ayudar al diseño del análisis y Pruebe los nuevos productos que ofrece. | Sí. W.Tenemos algunos como CE/SG |